Crafting fabric shoe storage boxes requires precision, creativity, and attention to detail. As a manufacturer, delving into the process of making these storage solutions not only enriches our understanding of the craft but also enables us to provide high-quality products that meet the diverse needs of our customers. Join me as we explore the intricate steps involved in the creation of fabric shoe storage boxes.

Fabric shoe storage boxes are essential organizers for individuals seeking to keep their footwear collection tidy and accessible. The process of manufacturing these boxes involves several key steps, each contributing to the overall quality and functionality of the final product.

Let’s delve deeper into the manufacturing process of fabric shoe storage boxes to uncover the nuances that make them both practical and aesthetically pleasing.

1 Selecting High-Quality Materials

The foundation of durable and visually appealing fabric shoe storage boxes lies in the selection of premium materials. Manufacturers carefully choose fabrics that are sturdy, breathable, and resistant to wear and tear. Common materials include polyester blends, canvas, and non-woven fabrics, chosen for their durability, flexibility, and ease of maintenance.

2 Precision Cutting and Assembly

Once the materials are sourced, the fabrication process commences with precision cutting and assembly. Advanced cutting machinery is employed to ensure accuracy and consistency in shaping the fabric pieces according to the predetermined dimensions. Skilled technicians then meticulously assemble the cut components, employing techniques such as stitching, heat sealing, or adhesive bonding, depending on the chosen fabrication method.

3 Adding Reinforcement and Structure

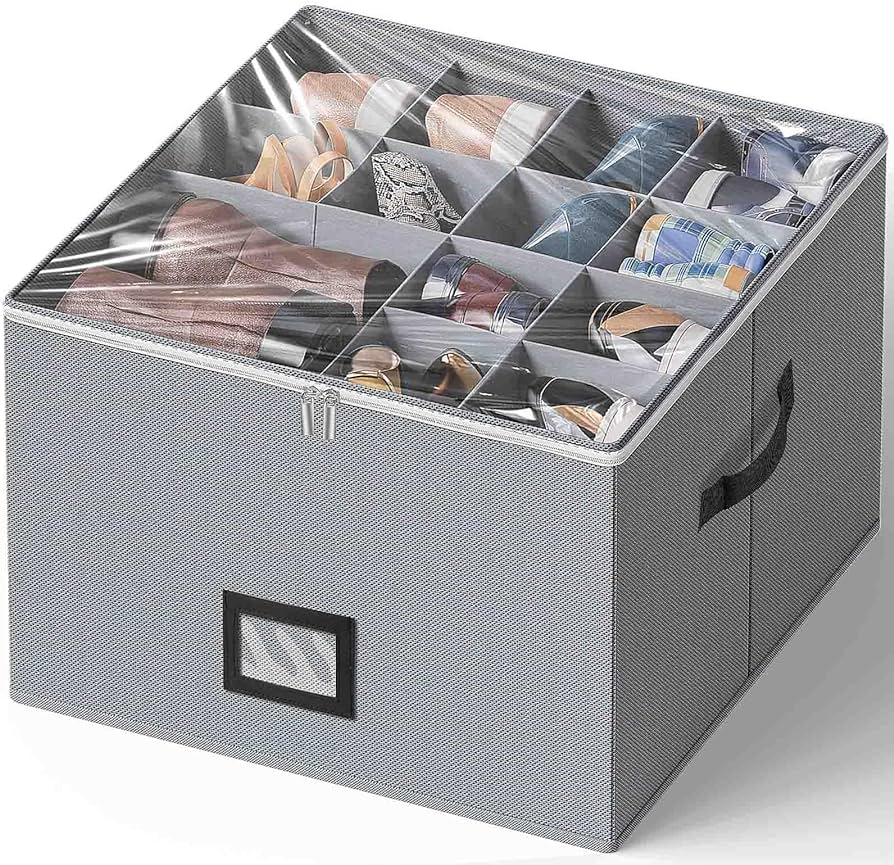

To enhance durability and structural integrity, fabric shoe storage boxes often incorporate reinforcement elements. Reinforced seams, sturdy handles, and supportive inserts are strategically integrated into the design to withstand the weight of multiple pairs of shoes and maintain the box’s shape over time. These reinforcements not only contribute to the longevity of the product but also enhance user experience by providing added stability and support.

4 Incorporating Functional Features

Manufacturers prioritize functionality by integrating a range of features that optimize storage and accessibility. This may include clear window panels for easy visibility, adjustable dividers to accommodate various shoe sizes, and secure closures to prevent dust and moisture infiltration. By incorporating these functional elements, fabric shoe storage boxes offer versatility and convenience to users, allowing them to organize their footwear collection with ease.

5 Quality Assurance and Testing

Before reaching the hands of consumers, fabric shoe storage boxes undergo rigorous quality assurance procedures to ensure they meet the highest standards of craftsmanship. Manufacturers conduct comprehensive testing, assessing factors such as seam strength, fabric durability, and structural stability. Additionally, prototype testing involving real-world scenarios allows manufacturers to identify any potential flaws or areas for improvement, ensuring that the final product surpasses customer expectations.

6 Eco-Friendly Practices

In alignment with sustainable manufacturing principles, many manufacturers prioritize eco-friendly practices throughout the production process of fabric shoe storage boxes. This may include using recycled materials, minimizing waste through efficient cutting techniques, and opting for environmentally friendly packaging solutions. By embracing sustainability, manufacturers not only reduce their environmental footprint but also appeal to eco-conscious consumers seeking responsible purchasing options.

Crafting fabric shoe storage boxes requires a blend of innovation, craftsmanship, and attention to detail. From meticulous design and material selection to precision assembly and quality assurance, each step in the manufacturing process contributes to the creation of functional and aesthetically pleasing storage solutions. By prioritizing quality, functionality, and sustainability, manufacturers can deliver products that enhance the organization and storage capabilities of individuals worldwide.