Ever wondered how those handy under bed storage bags are made? As a supplier, I’m excited to give you a behind-the-scenes look at the process. These storage solutions are crafted with care to ensure durability, functionality, and efficiency.

Under bed storage bags are made by selecting durable materials, cutting and sewing them into shape, adding features like zippers and handles, and conducting quality checks to ensure they meet high standards.

Want to know more about each step in the creation of these essential storage items? Read on to discover the details!

1 Material Selection

The first step in making under bed storage bags is choosing the right materials. Typically, manufacturers select durable fabrics like polyester or non-woven fabric, which are both strong and breathable. These materials are ideal for protecting items from dust, moisture, and pests.

Why It Matters

The choice of material is crucial because it directly impacts the durability and effectiveness of the storage bag. High-quality materials ensure the bag can withstand regular use and protect stored items.

2 Design and Cutting

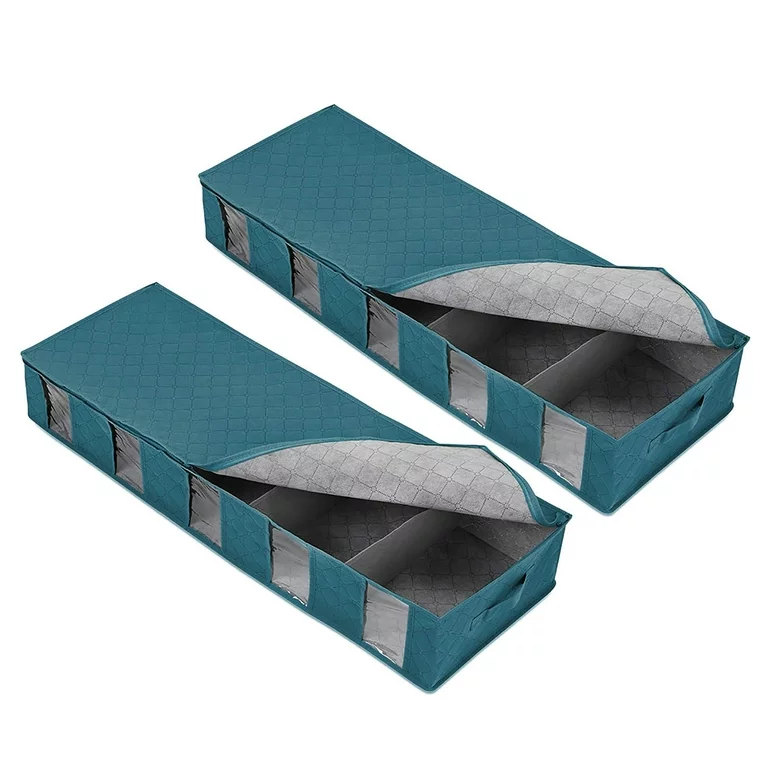

Once the materials are selected, the next step is designing the storage bag. This involves creating patterns and determining the bag’s dimensions, compartments, and additional features like handles and clear windows. After finalizing the design, the fabric is cut into the required shapes and sizes using precision cutting tools.

Why It Matters

A well-thought-out design ensures that the storage bag is not only functional but also convenient to use. Accurate cutting ensures minimal waste and contributes to the overall efficiency of the manufacturing process.

3 Sewing and Assembly

The cut pieces of fabric are then sewn together to form the structure of the under bed storage bag. Skilled workers use industrial sewing machines to stitch the pieces, ensuring strong and durable seams. This stage also includes adding zippers, handles, and any other design features.

Why It Matters

Proper sewing and assembly are critical to the bag’s strength and longevity. Quality stitching prevents the bag from falling apart under the weight of stored items, making it reliable for long-term use.

4 Adding Special Features

To enhance functionality, under bed storage bags often come with special features. This can include clear windows for easy identification of contents, reinforced handles for easy transportation, and zippered closures to keep dust and pests out. Some bags also have collapsible structures for easy storage when not in use.

Why It Matters

Special features add convenience and versatility to the storage bags, making them more user-friendly and suitable for various storage needs.

5 Quality Control

Before the storage bags are packaged and shipped, they undergo rigorous quality control checks. Inspectors look for any defects in the materials, stitching, and overall construction. They also test the zippers, handles, and other features to ensure everything functions correctly.

Why It Matters

Quality control ensures that each storage bag meets high standards of durability and functionality. This step is essential for maintaining customer satisfaction and reducing the likelihood of returns or complaints.

6 Packaging and Shipping

After passing quality control, the under bed storage bags are folded and packaged. They are typically packed in protective packaging to prevent damage during transit. Finally, they are shipped to retailers or directly to customers.

Why It Matters

Proper packaging protects the product during shipping and ensures it arrives in perfect condition. Efficient shipping practices also help in timely delivery, enhancing customer satisfaction.

Creating under bed storage bags involves a meticulous process of material selection, precise cutting, careful sewing, and rigorous quality control. Each step is designed to ensure the final product is durable, functional, and user-friendly. Understanding this process gives you a deeper appreciation for these handy storage solutions that help keep our homes organized and clutter-free.